Coatings Manufacturer

22/04/20251. Project Overview

This project involved a coatings manufacturer in Singapore adopting an advanced energy insight system to optimize operations across its facilities. The primary goals were to reduce energy consumption, lower operational costs, and improve sustainability practices.

2. Challenges Addressed

The manufacturer faced rising energy costs and inefficiencies in energy management, impacting their operational and environmental performance. Without detailed monitoring, it was difficult to identify high-energy-use areas or opportunities for improvement.

3. Solutions Implemented

The company deployed an energy insight system featuring machine-level metering, real-time reporting, and alerts. These tools provided detailed visibility into energy usage, enabling targeted efficiency measures and proactive management of energy-intensive processes.

4. Results and Impact

- Energy Savings: Achieved a remarkable 48% reduction in energy consumption, equivalent to 58,510 kWh saved annually.

- Cost Savings: Realized S$16,506 in savings within the first year alone.

- Sustainability Gains: Enhanced operational efficiency while significantly contributing to the company’s sustainability goals.

5. Lessons Learned

- Leveraging detailed energy insights helps uncover inefficiencies and optimize resource allocation.

- Proactive monitoring and alerts can lead to swift actions that result in immediate energy and cost benefits.

- Investing in energy efficiency tools delivers measurable returns and strengthens sustainability commitments.

6. Visuals and Data

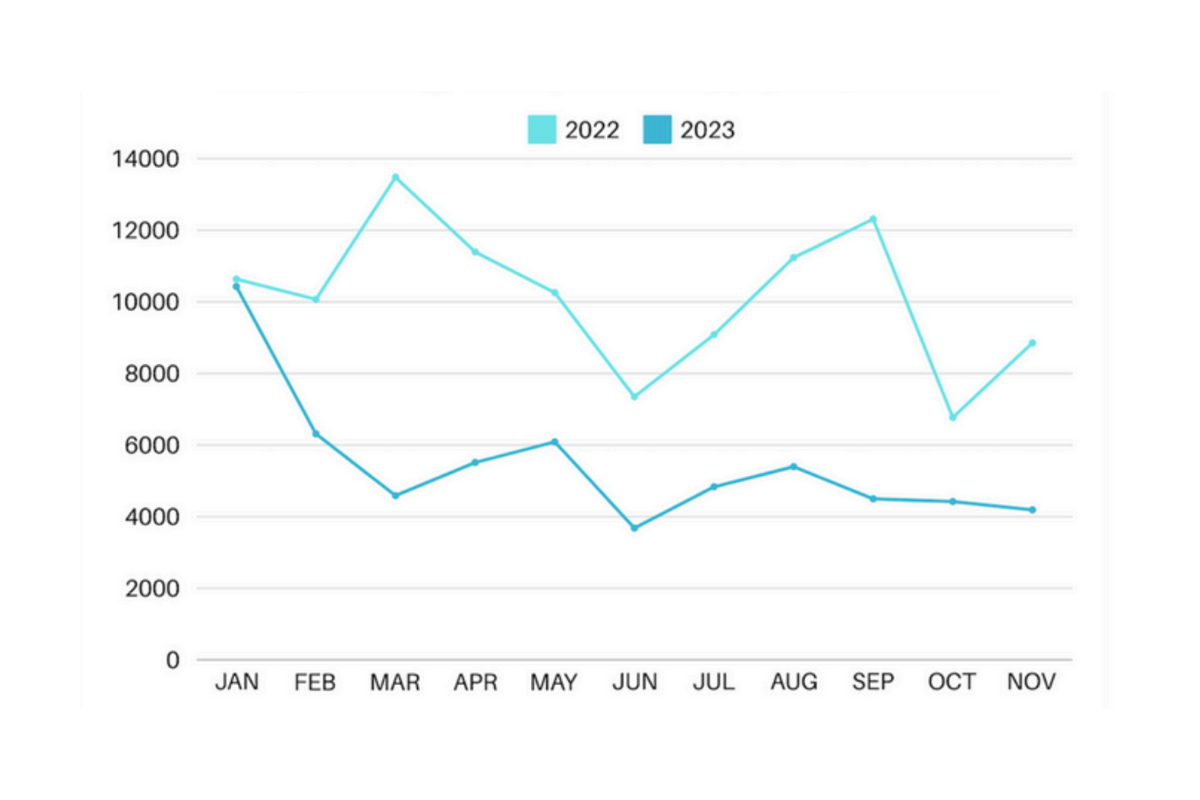

Including a chart showing the 48% energy consumption reduction or a graph of cost savings over time would provide a clear visual representation of the impact.

This case study demonstrates how energy insight systems can drive measurable improvements in cost and sustainability. Ready to unlock similar benefits? Contact us to learn more about our energy-saving solutions!

Try Ampotech

Contact our team to experience Ampotech’s energy solutions firsthand.

VI

VI